stainless steel pricelist

Home

Home- · door seal strip 3m exporter

- · thick door seal strip company

- · gasket seal strip exporters

- · ce cetification front door seal strip

- · led neon moon light supplier

- · led neon ribbon light product

- · pvc white board profile service

- · bathtub seal strip pricelist

- · sponge seal service

- · felt window seal strip suppliers

It is essential to factor in these additional costs when budgeting for pipe wrapping tape It is essential to factor in these additional costs when budgeting for pipe wrapping tape

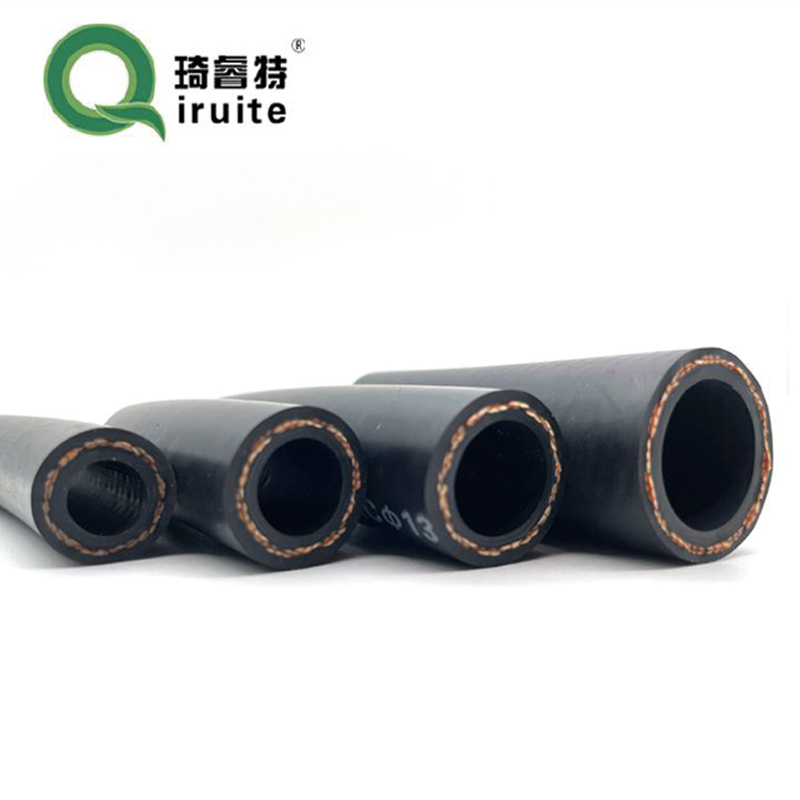

It is essential to factor in these additional costs when budgeting for pipe wrapping tape It is essential to factor in these additional costs when budgeting for pipe wrapping tape The high level of accuracy required in these applications highlights the importance of this component's design and manufacturing process The high level of accuracy required in these applications highlights the importance of this component's design and manufacturing process

The high level of accuracy required in these applications highlights the importance of this component's design and manufacturing process The high level of accuracy required in these applications highlights the importance of this component's design and manufacturing process

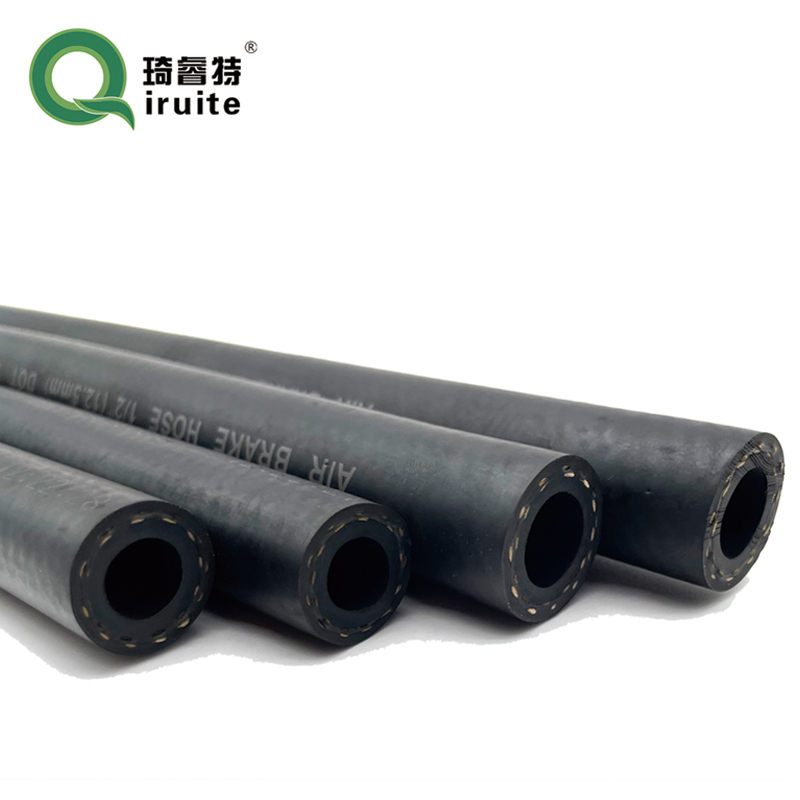

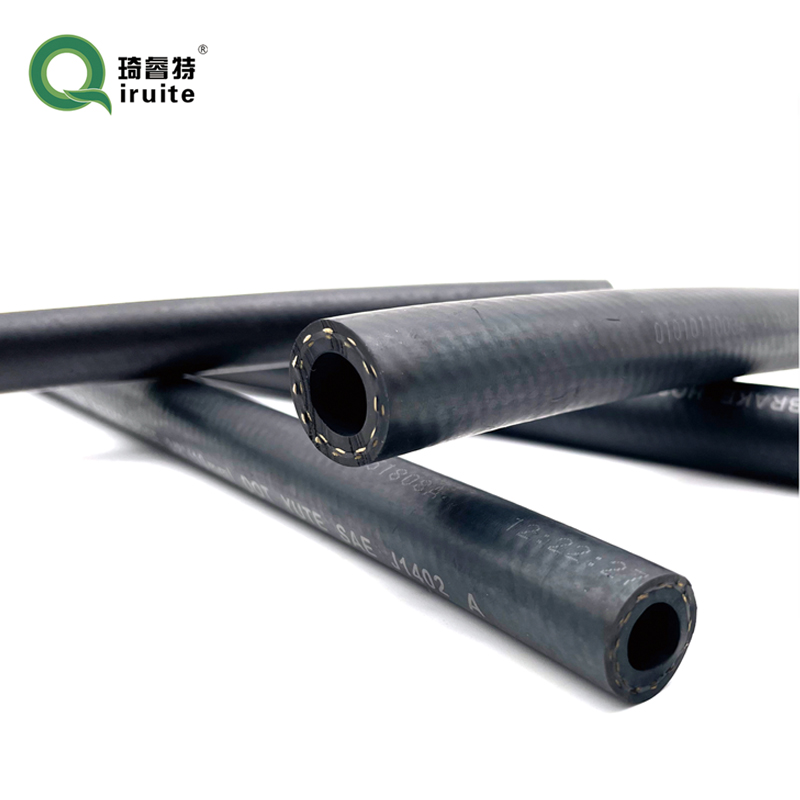

When the driver applies the brake pedal, the fluid pressure travels through the hose, causing the brake pads or shoes to press against the rotor or drum, thus slowing down or stopping the vehicle When the driver applies the brake pedal, the fluid pressure travels through the hose, causing the brake pads or shoes to press against the rotor or drum, thus slowing down or stopping the vehicle

When the driver applies the brake pedal, the fluid pressure travels through the hose, causing the brake pads or shoes to press against the rotor or drum, thus slowing down or stopping the vehicle When the driver applies the brake pedal, the fluid pressure travels through the hose, causing the brake pads or shoes to press against the rotor or drum, thus slowing down or stopping the vehicle The diagram will show how these elements are interconnected through the hoses, highlighting the path of the fluid flow The diagram will show how these elements are interconnected through the hoses, highlighting the path of the fluid flow

The diagram will show how these elements are interconnected through the hoses, highlighting the path of the fluid flow The diagram will show how these elements are interconnected through the hoses, highlighting the path of the fluid flow